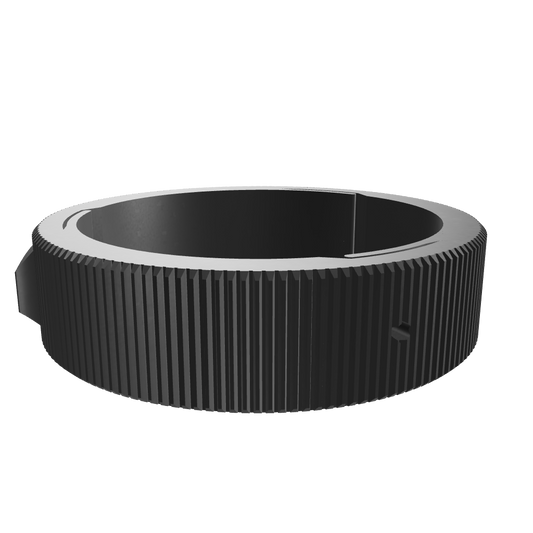

Follow Focus Rings – precise, clamped, custom-made

Gentle clamping mechanism that won't damage your lens, optimized for 0.8 MOD focus motors. No more slipping.

Order your custom-made order now!

Follow Focus Rings

Measurement guide: How to determine your size

You only need two measurements: the inner diameter (ID) of your lens and the desired width (W), which is 14mm by default.

The outer diameter (OD) is optional – e.g., if several rings are to have the same outer diameter.

If no AD value is specified, the standard is: wall thickness 10 mm → AD = ID + 20 mm .

Method A

Measure the diameter with calipers.

Method B

Wrap a strip of paper around the lens and mark it. Then measure and convert the measurement using the calculator below.

Tip: It's best to round up to the nearest whole millimeter – for example, a measurement of 63.3 mm results in an order value of 64 mm. If you are measuring the paper roll (Method B), enter the number into the calculator below to get the diameter.

Quick calculator

Convert circumference (mm) to diameter (mm).

⛭

The Problem

I've tried various Focus rings over the years – and they all had drawbacks:

- Rigid PETG rings without clamping: their hold varies depending on the temperature. If you lift the lens by the ring, it can slip off – in the worst case, the lens falls out.

-

Rubber rings with size range: they fit snugly, but the flexible teeth give way – during fast pulls or motor calibrations, the drive gear slips over them.

- Clamping rings with grub screws for the lens: they eliminate slippage, but quickly scratch the tube/mount.

- Furthermore: Many systems only work if your lens is in their database – otherwise it will be expensive as a custom order .

Design philosophy

That's why I developed my own ring that eliminates these problems:

- Secure clamping mechanism without screws on the lens – excellent form fit, non-slip, gentle.

- Stiff, precise teeth for clean meshing with the focus motor – no slippage during fast moves.

- Temperature-stable material selection for reproducible clamping force and long service life.

-

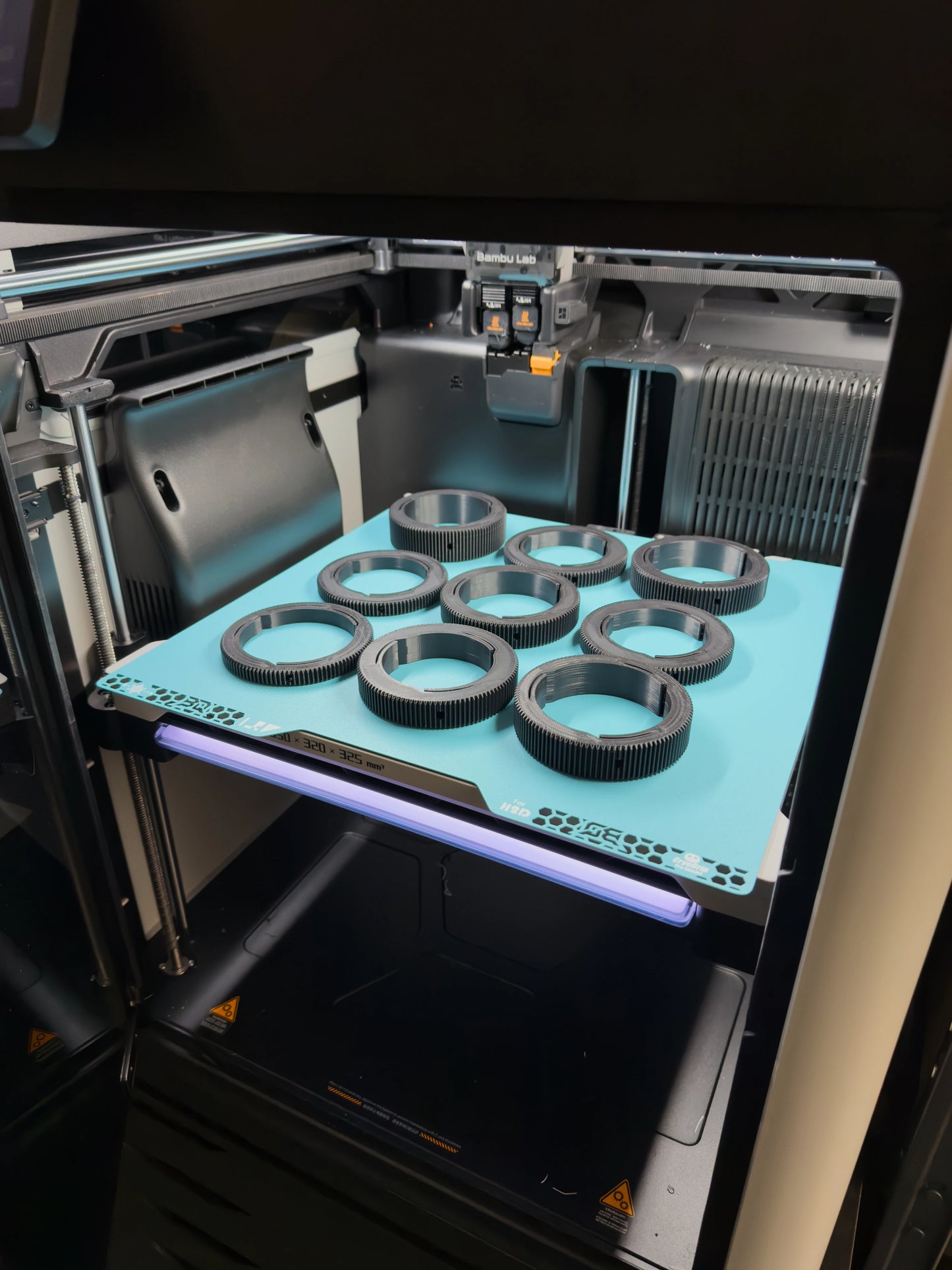

Parametric design: I only enter the inner diameter (ID) and width – all geometries adjust automatically.

Result: Individually tailored instead of database gambling – and quickly produced.

Why this is better for you

You get precision-cut rings without the risk of scratches, consistent performance during motor pulls and calibrations – and thanks to my parametric workflow , custom designs at a fair price . Designed and manufactured in Vienna .

- Gentle clamping – no pressure marks on vintage lenses.

- Constant outer diameter allows for faster lens swaps.

- Rough micro-finish for a secure grip on the focus motor.

Packaging & Sustainability

We ship 100% cardboard-based – the envelope and padding are made from recycled cardboard, without any additional plastic . Short routes from Vienna to the EU.

CO₂ offsetting: We compensate for the filament and shipping footprint with double the equivalent value.

Material & Origin

Made from ASA by Extrudr – sourced in Austria (Vorarlberg). ASA is dimensionally stable, UV-resistant and ideal for precise, durable focus gears.

Suitable for outdoor use

clean tooth flanks

short supply chains

Assembly in 60 seconds

Assembly in 60 seconds

- Make sure to set the lens focus to infinity before you begin.

- Slide the ring loosely over the focus knurling.

- Position evenly, then tighten the small screws evenly using the supplied Allen key – not too tightly.

- Push the motor in, check the backlash , turn it – done.

Note: Do not overtighten. The clamp is designed to hold with moderate torque.

Note: Do not overtighten. The clamp is designed to hold with moderate torque.

FAQ

Will the ring damage my lens?

No. The clamping geometry distributes the forces over a wide area, and the ring is designed to hold with gentle, firm hand-tightening. The ASA material is rigid yet minimally flexible to prevent pressure marks on vintage lenses.

What is the difference between ASA and PLA/PETG?

ASA is an engineering plastic that is extremely UV-resistant and dimensionally stable up to temperatures exceeding 90°C. Unlike PLA (which can deform in a hot car) or PETG (which is less rigid), ASA retains its shape and function under professional conditions.

What if I mismeasure myself?

Please contact us before ordering if you are unsure about your size. As each ring is custom-made, we unfortunately cannot accept returns for incorrectly ordered sizes. However, we are happy to help you find the exact measurements via email.

How long does shipping and production take?

We produce on-demand in Vienna. Your ring is usually produced and shipped within 48 hours. Shipping within Austria typically takes 1-2 business days, and to Germany 2-4 business days.